The thermal energy storage (TES) can be defined as the temporary storage of thermal energy at high or low temperatures. The TES is not a new concept, and at has been used for centuries. Energy storage can reduce the time or rate mismatch between energy supply & demand and it plays an important role in energy conservation.

Latent heat storage (LHS) is based on the heat absorption or release when a storage material undergoes a phase change from solid to liquid or liquid to gas or vice versa.

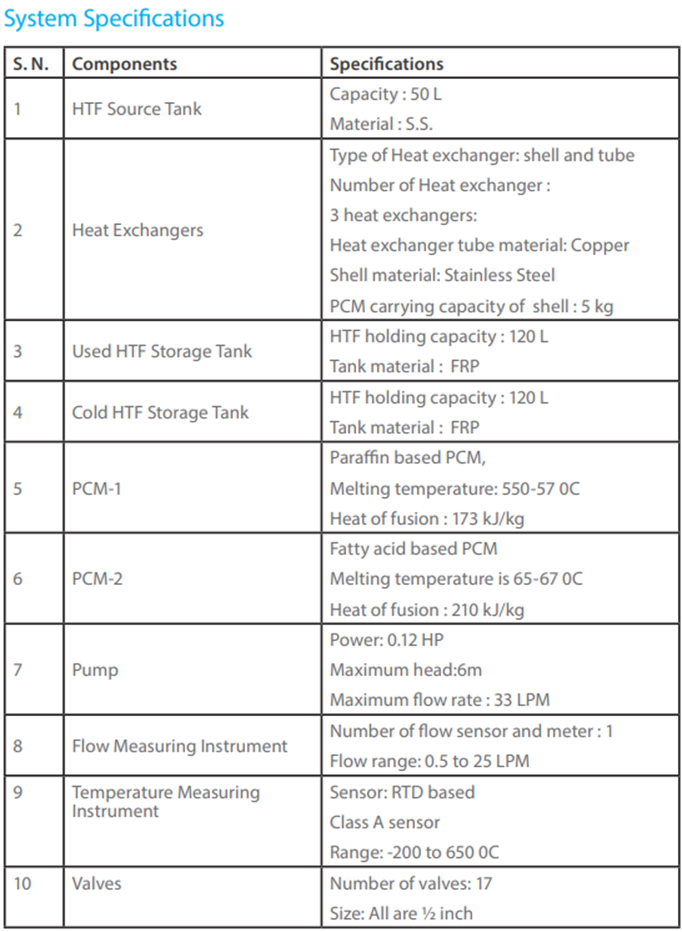

Stainless steel cylinders are used to contain the PCMs. To charge and discharge (store and extraction of heat) the PCMs, spiral type heat exchangers made of copper of appropriate dimensions are installed in the containers. The PCMs and heat exchangers are meticulously arranged inside the S.S cylinders. In order to block heat loss from the PCM, all the cylinders are insulated by polyurethane (PUF) foam insulation.

Water is the heat transferring fluid (HTF) in the system. While hot water gives heat to the PCM during charging, the cold water absorbs heat from the same PCM during discharging. To supply water for different purposes, three tanks are there in the system. For source of energy, special arrangement has been made within the system. Besides the integrated arrangement, the system can also be connected with flat plate solar collector or parabolic trough solar collector for the source of energy. Different parts of the systems are connected with G.I/PVC pipes of ½ inch size. To direct the heat transferring fluid as per requirement several gate valves are there in the appropriate locations. To measure different variables such as temperature, flow rate, etc., respective sensors are placed at the targeted points. There is a control unit in the system where all meters and control buttons are strategically arranged to display the reading from the respective sensors.